A filter press is a type of industrial equipment used for separating solids and liquids. It works by applying pressure to a slurry (a mixture of solid and liquid particles) to force the liquid through a filter medium, leaving the solid particles behind. The filtered liquid is then collected and the solid particles are removed from the filter plates.

The basic function of a filter press is to separate solid particles from a liquid in order to purify the liquid or to recover the solid particles. This process is commonly used in many industries, such as mining, food processing, wastewater treatment, and chemical manufacturing, to name a few.

Filtration is aprocess most often used for the separation pf solids from liquids in which they are suspended. The aim of the operation is the recovery of filtered liquid solids in form of cake or sometimes both.

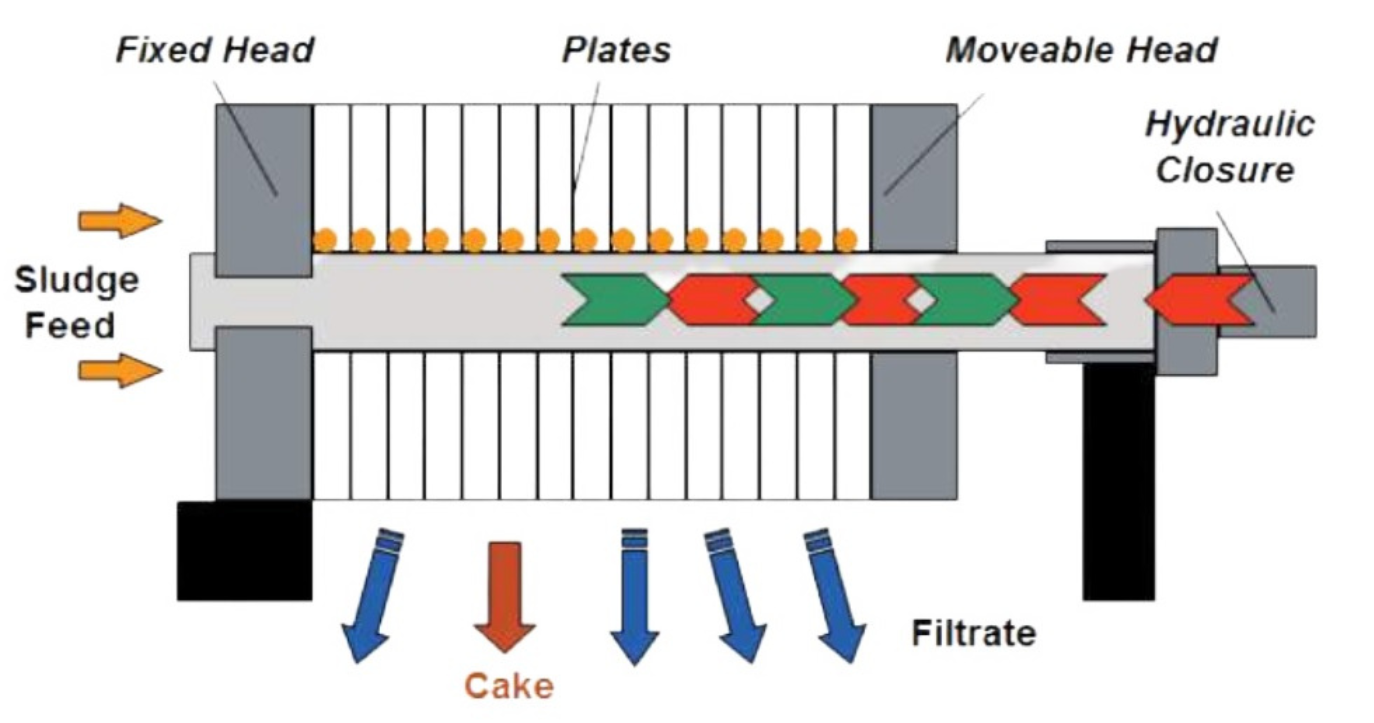

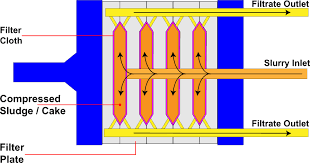

Filtration of a solid liquid suspension is carried out under pressure in a closed container system provided with chamber plates wrapped in the filter cloth into which the suspension is normally pumped.

The working pressure chosen according to the specific needs normally ranges between 2-20 bars. The entire assembly is kept leak tight by a suitable closing device which has force equivalent to that of the maximum feed pressure or membrane squeeze pressure.

During discontinuous cake filtration with filter presses, the suspension to be filtered in pumped and concentrated via the turbidity inlet into the filter plate chambers. The driving force for the liquid transport is provided by a feed pump. The filter plates are lined with special filter cloths according to the respective application. These cloths retain the solids in layers during the flow. A layer of the solids to be separated accumulates over time.

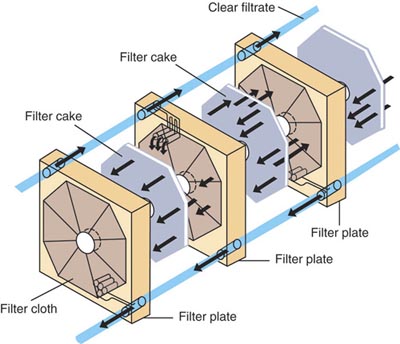

This layer is known as the filter cake, which remains in the plate chamber as solid mass and makes a significant contribution to the filtration of the liquid. The filtrate, which penetrates the filter cloths, is discharged along a channel system via the filtrate drain introduced into the filter plates. As the layer to be flowed through grows, the flow through resistance increases and with it the pressure loss, with a concomitant products. This leads to inefficient and uneconomically long filtration times. With periodic cake filtration, the filtration process is interrupted once a predetermined pressure has been reached. If necessary, the filter cake is squeeze - treated (membrane technology) and then removed by opening the filter press. After optional cleaning and closing of the unit, filtration starts again from the beginning. The filtration cycle is essentially divided into four phases.

The decisive parameters for assessing a filtration process with filter presses are the filtration pressure and the throughput. In an ideal filtration process, the filtrate the building up filter cake is what offers the filtrate the filtration pressure only chambers of the such as particle size distribution, particle shape and interaction between the cake resistance and the associated filtration process cannot approaches. Preliminary tests are therefore our laboratory, we create the laboratory filter The filtration cycle is essentially divided into four phases: can drain off freely. Only resistance to the filtrate flow. This means that increases significantly when the filter cake is compressed in the filter press. Since the resistance of a filter cake depends on numerous factors, particles, a filter simply be predicted by theoretical necessary to determine the filter cake resistance. In basics for the best possible filtration on your filter press using presses.

A filter press typically consists of a series of filter plates, each with a filter cloth or membrane, that are arranged in a stack. The slurry is introduced into the filter press and forced through the filter medium under pressure, separating the liquid and solid components. The filtered liquid is then collected and the solid particles are removed from the filter plates.

Filter presses can be used in a variety of applications and can be designed to handle a wide range of flow rates and solids concentrations. They can be configured as batch filter presses, where the entire process is carried out in a single cycle, or as continuous filter presses, where the filtration process is ongoing.

Overall, the function of a filter press is to separate solids and liquids, making it a useful tool for many industrial processes that require the separation of these components.

Frame (Skeleton): The steel filter press frame serves as a clamp for the filter plates.

Filter Plates: There are 3 main sorts of filter plates, each with a unique set of uses. Plate and frame, sunken chamber (or recessed plate), and diaphragm squeeze (also known as membrane squeeze).

Manifold: Our typical manifold is made up of piping and valves. They manage the slurry inlet and link the four corner filtrate discharge ports to a single discharge pipe.

Filter Cloth: The filtering medium is a cloth filter that is attached to the filter plate. Solids accumulate on fabric to create a filter cake that separates liquids from solids.

The dewatering volume and slurry type essentially determine how the filter press is designed. Maruti Filters is a leader in liquid and solid separation and provides a comprehensive selection of filter press types and capacities to meet various application requirements for hassle-free, cost-effective dewatering.

A filter press is a machinery component used to separate particulates from liquids. It functions by applying pressure to drive a liquid through a sequence of filter plates loaded with a filter media, such as cloth or paper.

The liquid and solid mixture to be filtered is placed within the filter press.

The filter press's plates are piled on top of one another, and each plate has a frame surrounding it with filter paper or cloth fastened to it.

Using a hydraulic or mechanical system, the plates are forced together to form a seal around their edges.

Increasing the pressure causes the liquid to be forced through the filter medium while the particles are left behind on the filter cloth or paper.

The filtered liquid is collected in a container so that it can be used again or disposed of as necessary.

The solids are taken from the filter plates in the filter press when the filtration procedure is finished.

A filter press is a machinery component used in several industries to separate solids from liquids. By applying pressure to a filter material, it is intended to separate liquids from solids. The filter medium is commonly a cloth or paper filter that traps the solids while allowing the liquid to pass through.

Industries include chemical manufacture, pharmaceuticals, mining, the production of food and beverages, and wastewater treatment frequently use filter presses. They can be used to dewater sludge, clarify liquids, clean up contaminants in liquids, and gather solids for disposal, among other things.

A hydraulic cylinder or mechanical screw holds a stack of plates in place in a filter press. The liquid that needs to be filtered is pumped into the press, and the plates are coated with a filter material. The solids are trapped on the surface as a result of the pressure forcing the liquid through the filter media. When the press is full, the plates are separated, and the solid cake is taken out and thrown away.

In general, filter presses are an efficient and effective approach to separate solids from liquids in a variety of sectors.

Here is a basic diagram of a filter press:

Feed Pump: The feed pump sends the slurry (a mixture of liquid and solids) to the filter press.

Feed Distribution Manifold: The manifold evenly distributes the slurry across the filter plates.

Filter Plates and Cloth: The filter plates are stacked together with filter cloth in between them. The slurry passes through the cloth and the solids are trapped on the cloth while the filtrate (the liquid that has passed through the cloth) goes through the filter plates.

Filtrate Collection Trough: The filtrate is collected in a trough below the filter plates and is then discharged from the filter press.

Filter Cake Discharge Chute: The solids that are trapped on the filter cloth form a layer called the filter cake. The filter cake is then discharged from the filter press.

A filter press is a device used in various industrial processes to separate solid and liquid materials by applying pressure to a slurry. The material is fed into a filter press and the liquids are separated from the solids through the use of filter plates and a sludge pump.

The main application of filter presses are in:

Wastewater treatment

Mining and mineral processing

Chemical production

Pulp and paper production

Dye and pigment production

Filter presses are available in a variety of sizes and configurations, making them suitable for a range of applications and industries. The choice of filter press will depend on the type and volume of the material being processed, the required solids separation efficiency, and the desired end product.

Filter presses have several features and benefits that make them a popular choice in various industrial applications. Some of the key features and benefits are:

High efficiency: Filter presses have a high efficiency of solid-liquid separation, making them suitable for applications where a high degree of separation is required.

Easy operation: Filter presses are relatively easy to operate and require minimal training, making them suitable for a wide range of operators.

Low maintenance: Filter presses are designed to be low maintenance, reducing the need for frequent servicing and minimizing downtime.

Customizable: Filter presses are available in a range of sizes and configurations, making them suitable for a wide range of applications and industries.

Consistent quality: Filter presses produce a consistent quality of solid and liquid materials, ensuring that the end product meets the desired specifications.

Environmentally friendly: Filter presses produce minimal waste and can be easily integrated into existing process lines, making them a more environmentally friendly option compared to other separation technologies.

Safe operation: Filter presses are designed to be safe to operate, with various safety features such as automatic shutdowns, pressure relief valves, and emergency stop buttons.

In summary, filter presses offer a range of features and benefits that make them a popular choice in various industrial applications, including wastewater treatment, mining and mineral processing, chemical production, pulp and paper production, and dye and pigment production.

A Maruti Filters closing device is a critical component of a filter press, as it is responsible for clamping the filter plates together, creating a sealed chamber for the slurry to be processed. There are several different types of closing devices used in filter presses, including:

Screw closure: A screw closure uses a large screw mechanism to clamp the filter plates together, creating a sealed chamber. This type of closing device is typically used in older or manual filter presses.

Hydraulic closure: A hydraulic closure uses hydraulic cylinders to clamp the filter plates together, creating a sealed chamber. This type of closing device is typically used in modern, automated filter presses.

Pneumatic closure: A pneumatic closure uses air pressure to clamp the filter plates together, creating a sealed chamber. This type of closing device is typically used in smaller filter presses.

Regardless of the type of closing device used, the main goal is to provide a secure and effective seal, allowing for maximum pressure to be applied to the slurry and maximum solids separation efficiency. The choice of closing device will depend on the size and type of filter press, as well as the type of material being processed and the desired level of automation.

| Brand | Maruti |

|---|---|

| Product | Filter Press |

| Usage/Application | Industrial |

| Size | 470MM x 470MM to 1500MM X 1500MM |

| Order Quantity | Minimum - 1 |

To know more, check out our helpful blog post on Filter Press.

Get in touch with Maruti Filtration right now if you're curious to learn more about how a filter press could be tailored for your particular purpose. Also, we could now have the ideal standard or used filter press in store to satisfy your demands. To take advantage of our expertise in designed filtration, Contact with Maruti Filtration right away.

470 MM X 470 MM

610 MM X 610 MM

800 MM X 800 MM

915 MM X 915 MM

1000 MM X 1000 MM

1200 MM X 1200 MM

1500 MM X 1500 MM