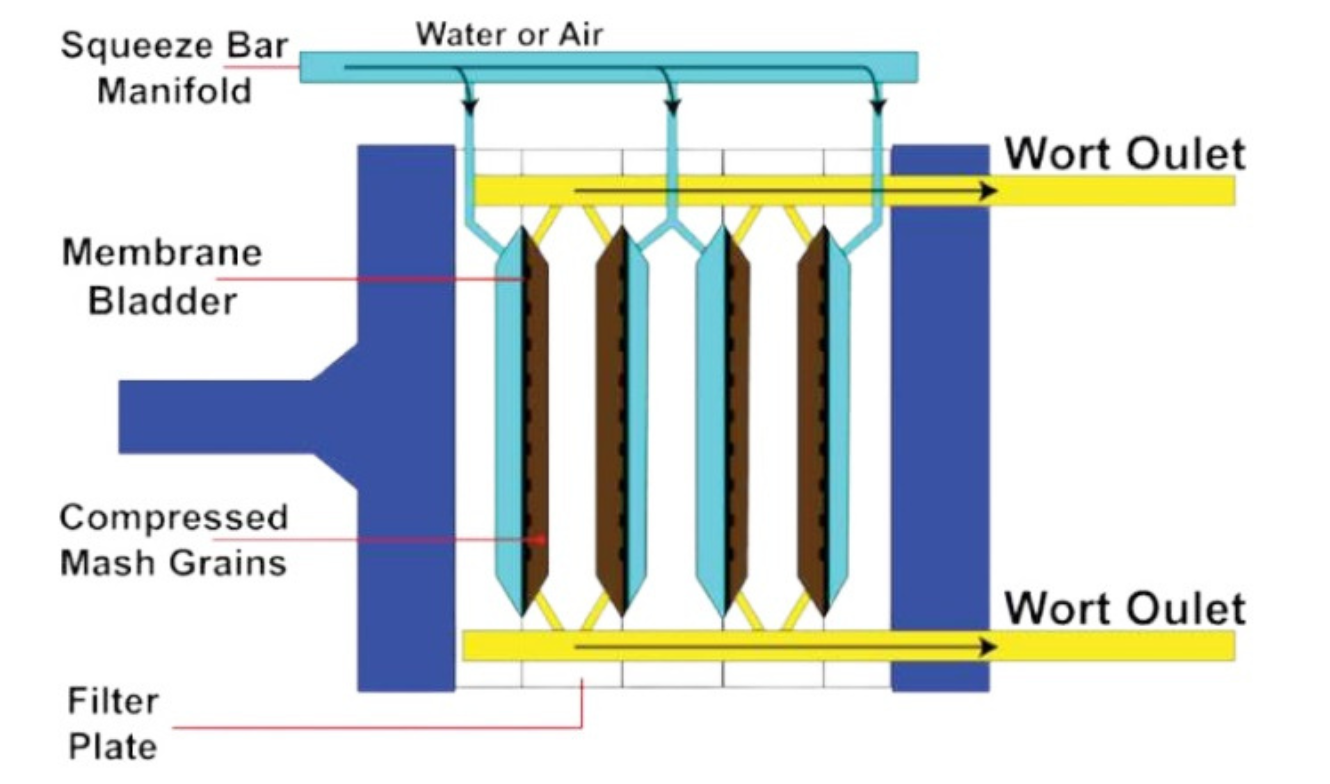

Membrane Filter Press are designed similar like chamber plates described above. A flexible membrane is fixed to the support body. The material for the membranes is polypropylene. The membrane is impermeable and compresses the cake within the chamber after the filtration process is completed. Liquid or air (compressed air) can be used as membrane inflation media.

Short filtration cycles

Short washing cycles

Low residual moisture

No direct load on membrane due to press closing force

High elasticity of membrane

Time-independent membrane movement

Sealing of filter plate system

Large cross-sectional area of filtrate outlet

Safety factor of the membrane system

There are two kinds of membrane plate, integrated membrane plate and CGR membrane plate. Maruti membrane plates are characterized by uncomplicated constructional setup, high functional security, anti-fatigue, anti-aging, and good sealing performance.

Mixed pack membrane filter plates are a configuration in which one recessed (chamber) filter plate is alternated with one membrane plate in the filter press plate pack.

Use of these mixed packs – where the diaphragm (membrane squeeze) plates alternate with the recessed plates – not only delivers reduced cake moisture because of the added squeeze but also cost-savings in overall plate pack costs vs. the full membrane squeeze pack design.

In most applications, the same process improvements can be realized with a “mixed pack” membrane filter plate system at 30-40% lower costs as compared to an all membrane plate system.

Two types of membrane squeeze plate designs are typically used, fixed membranes and replaceable membranes.

With the replaceable membrane, only the membrane bladder is changed not the full plate.

There are also other design options including either center feed or corner feed.

Sealing of filter plate system

Large cross-sectional area of filtrate outlet

Maruti filtration specialists can work on selection of just the right filter plate materials of construction and configuration for your particular application and for your production goals.

Membrane filter presses have a great influence on the dryness of the solid by using membrane technology in the filter plates. A flexible, impermeable membrane attached to the carrier body compresses the cake in the chamber after the feeding process is complete.

The membrane technology not only offers the advantage of an extremely high degree of dewatering. Furthermore, the filtration cycle time is additionally reduced, on average by more than 50 percent, depending on the suspension through the membrane filtration. This results in faster cycle and turnaround times, which lead to an increase in productivity.

Even with partially filled filter chambers, excellent dry matter results can be achieved thanks to membrane technologies. Even with abrasive media, for example, pump wear is decreased by reduced feeding pressure (6-8 bar depending on the suspension) without affecting the final result. Depending on the degree of dewatering, different dry matter contents(dry matter content percentage by weight of dry material in the filter cake) can be achieved in the filter cake by squeezing with membrane plates. The range of achievable dry matter contents extends from 30 to over 80 percent. In the standard version, squeezing is also carried out on both sides. Depending on the medium to be filtered, there is also the option of only using membrane technology for every second filter plate. The combination of membrane filter plates and chamber filter plates (mixed package) reduces the initial costs and also guarantees excellent filtration results. This type of filter press is called the chamber membrane filter press.

630 MM X 630 MM

800 MM X 800 MM

1000 MM X 1000 MM

1200 MM X 1200 MM

1500 MM X 1500 MM

2000 MM X 2000 MM